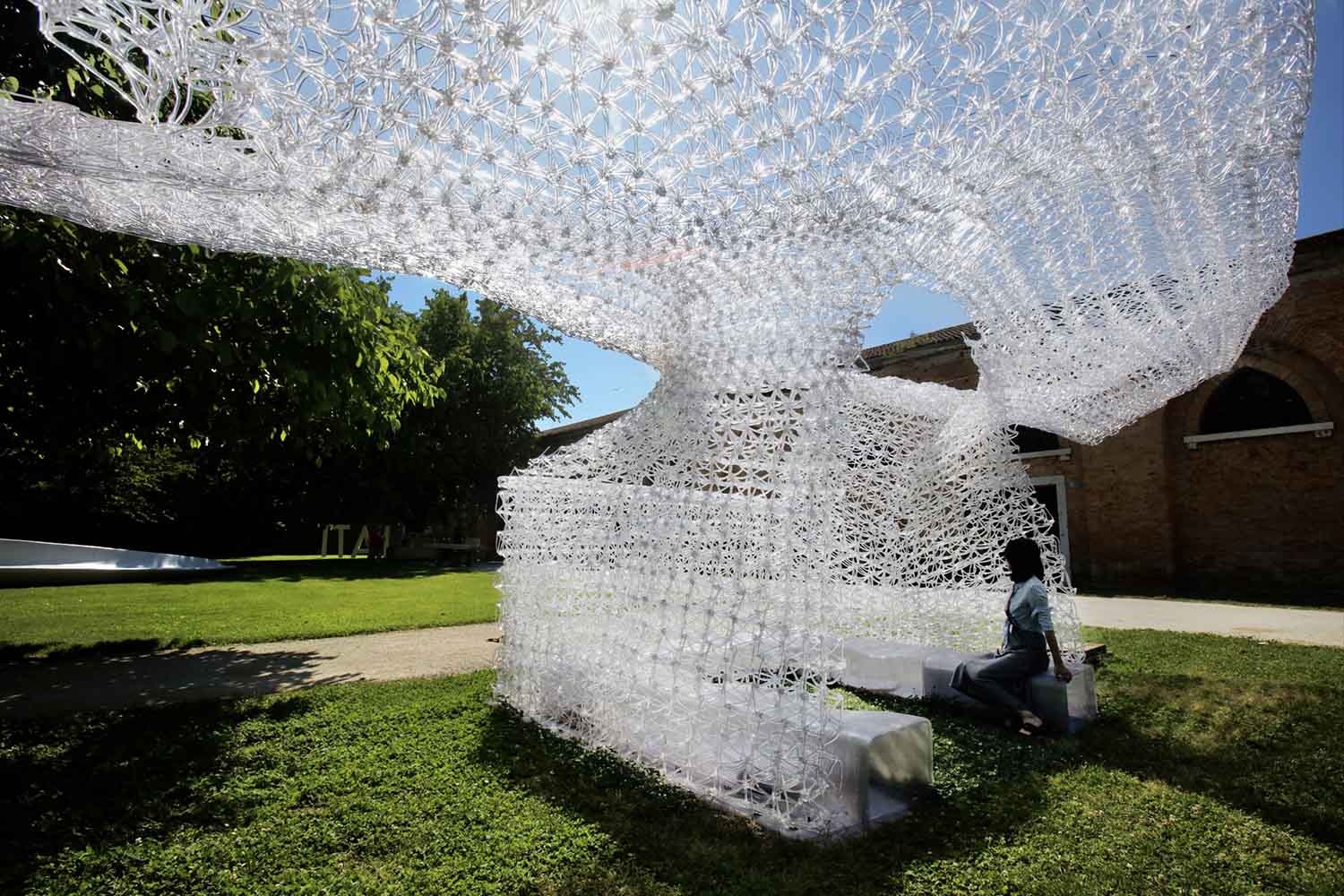

China Outdoor Pavilion Cloud Village in Biennale Architettura 2018 will be built with modified plastic material by the robotic printing technology, developed by the Philip F. Yuan and his team. Cloud Village reflects the contemporary reality of Chinese country side through its semiotic performance of materiality. The recycled plastic material of the pavilion indicates the crisis of the environmental issue of contemporary Chinese country side, and establishes a critical rethinking on the sustainable way of spatial production for the future.

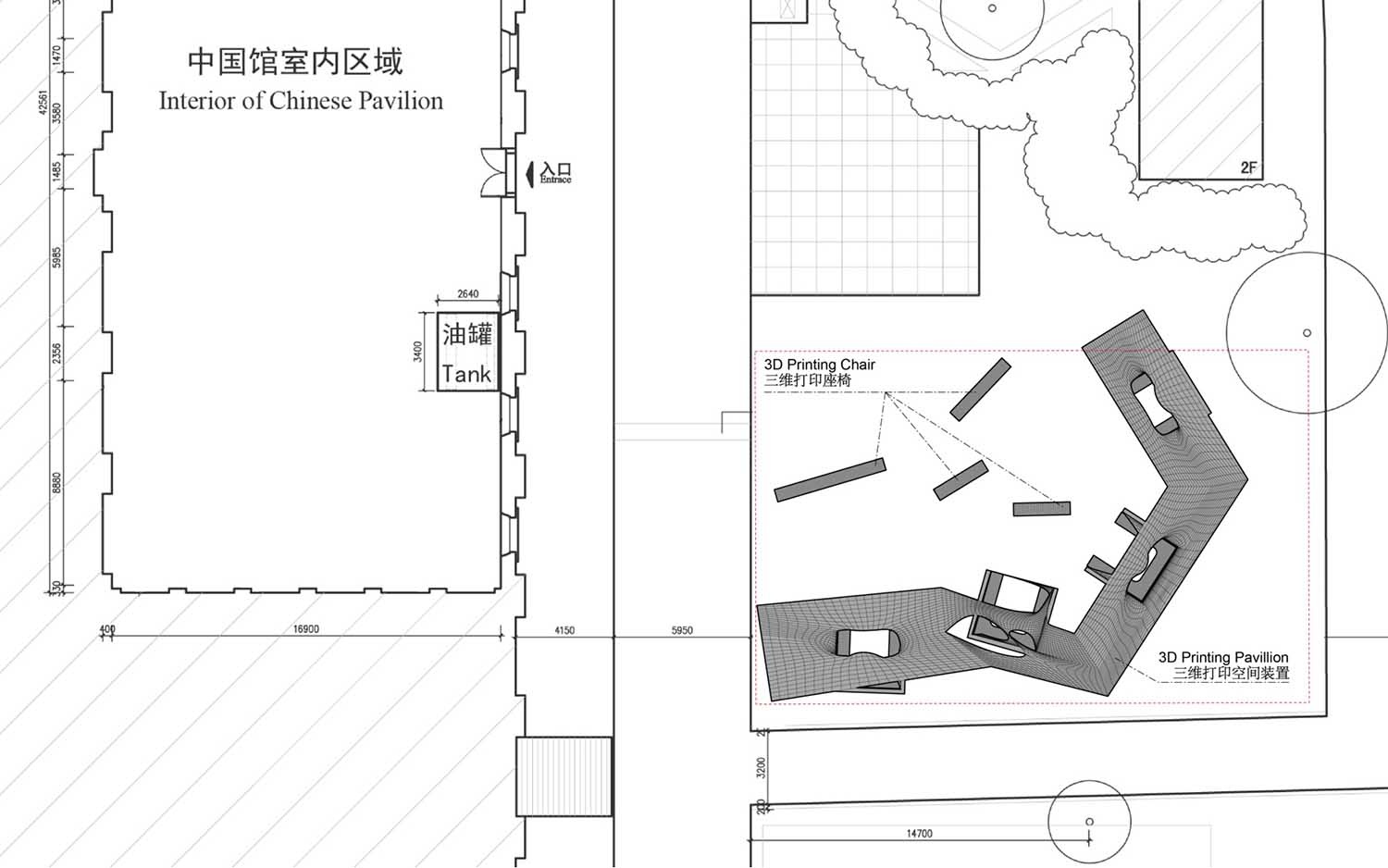

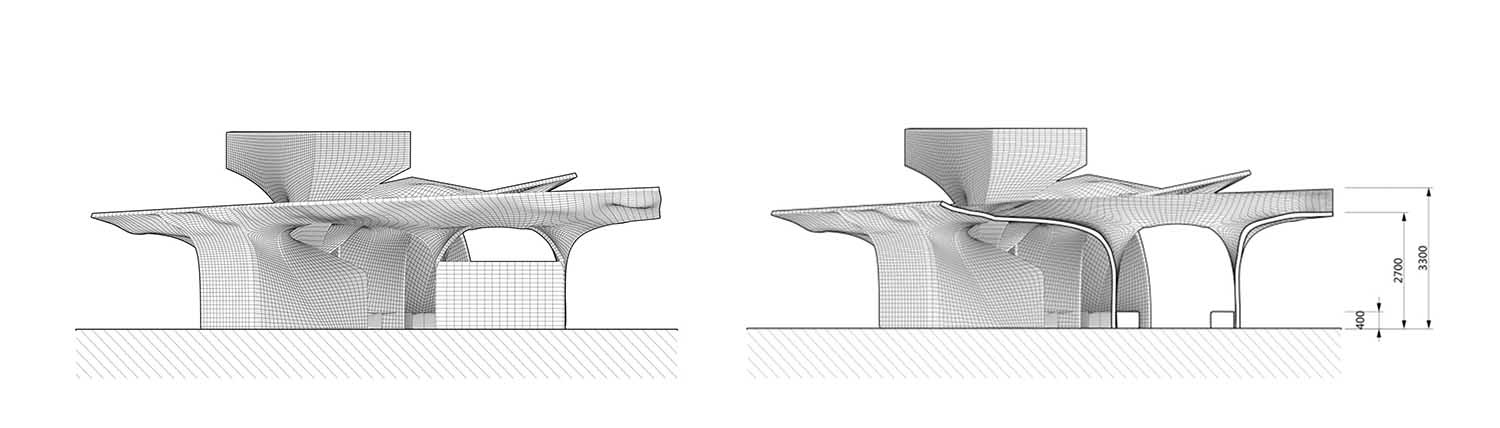

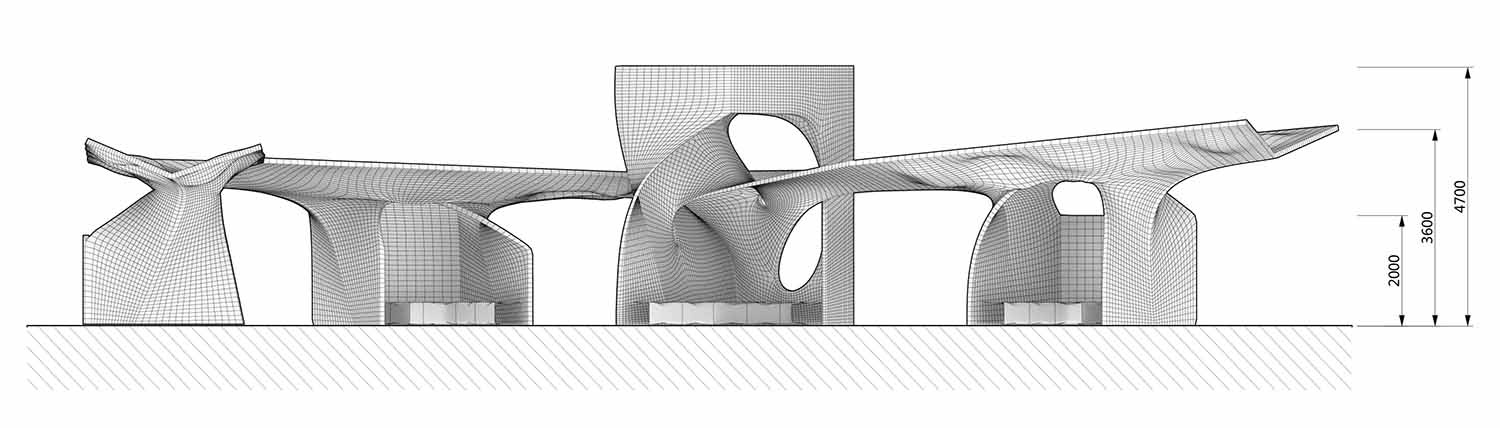

In response to the theme of the Chinese Pavilion—Building a Future Countryside, the spatial distribution of Cloud Village pavilion is an abstract representation of everyday life in the country side. The pavilion contains four semi-enclosed cubic objects, which are organized together by a shared linear roof. As all the “private spaces” completely opens to this central public space, the boundary between them would only be defined by the roof. Consequently, there would be no clear distinct between the private and the public as well as the individual and the collective. In the end, this kind of spatial uncertainty produces a latent atmosphere for the site to destabilizing the identity of each occupant.

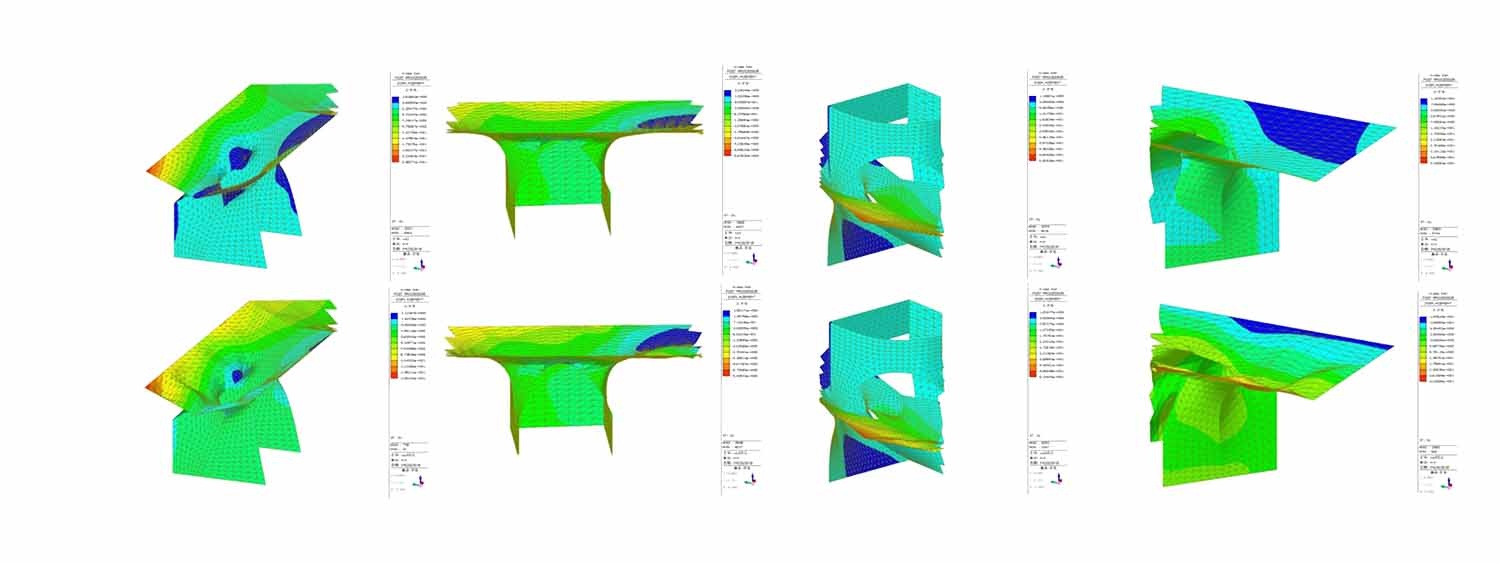

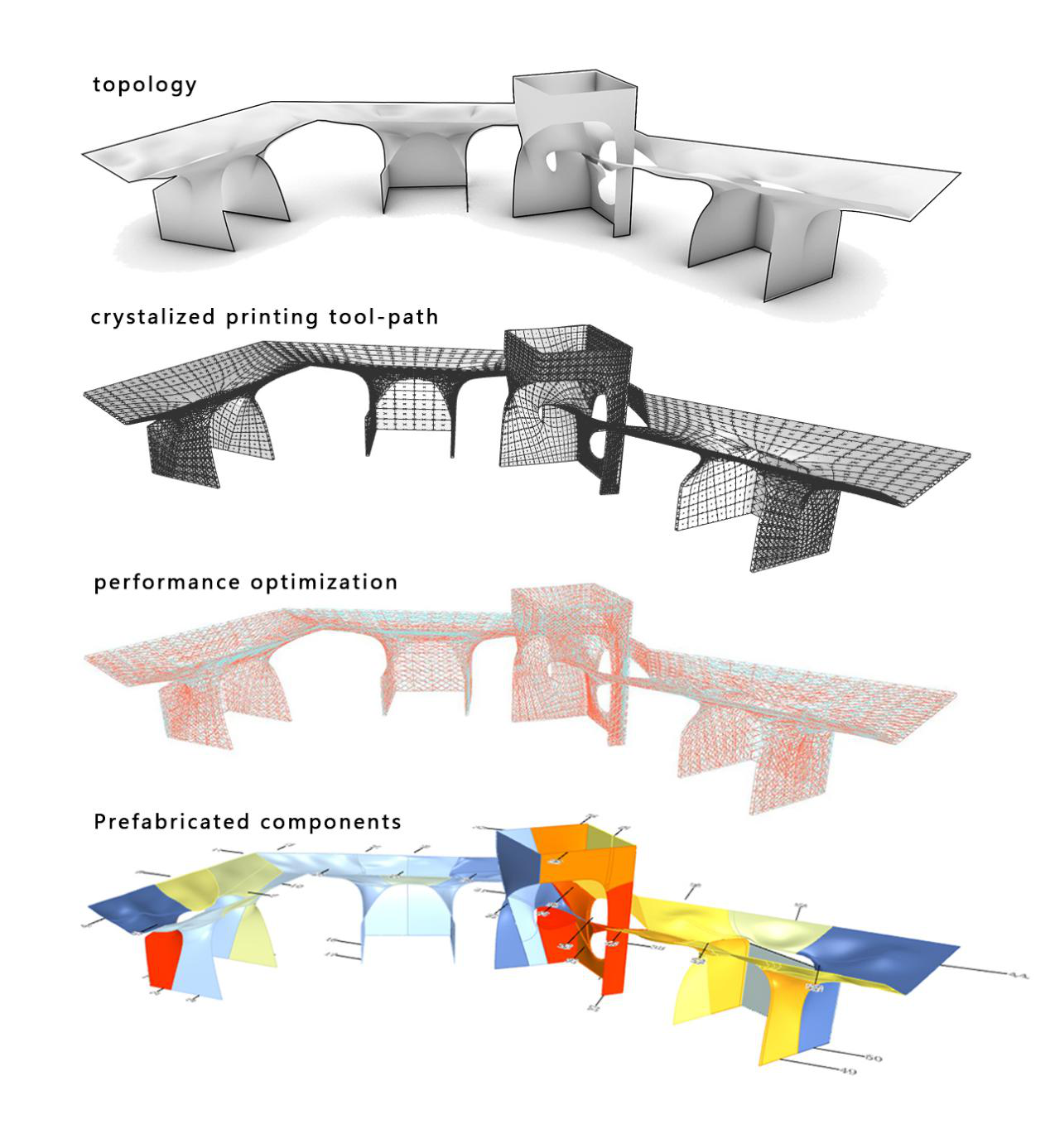

The pavilion aims to combine structural performance-based design methodology with robotic fabrication technology in a highly integrated process. The form of the pavilion is optimized by adopting a series of topological optimization algorithm to enhance the overall structure performance. By turning the flat roof into the waved geometry, the structural stiffness of the cantilever roofs is highly increased.

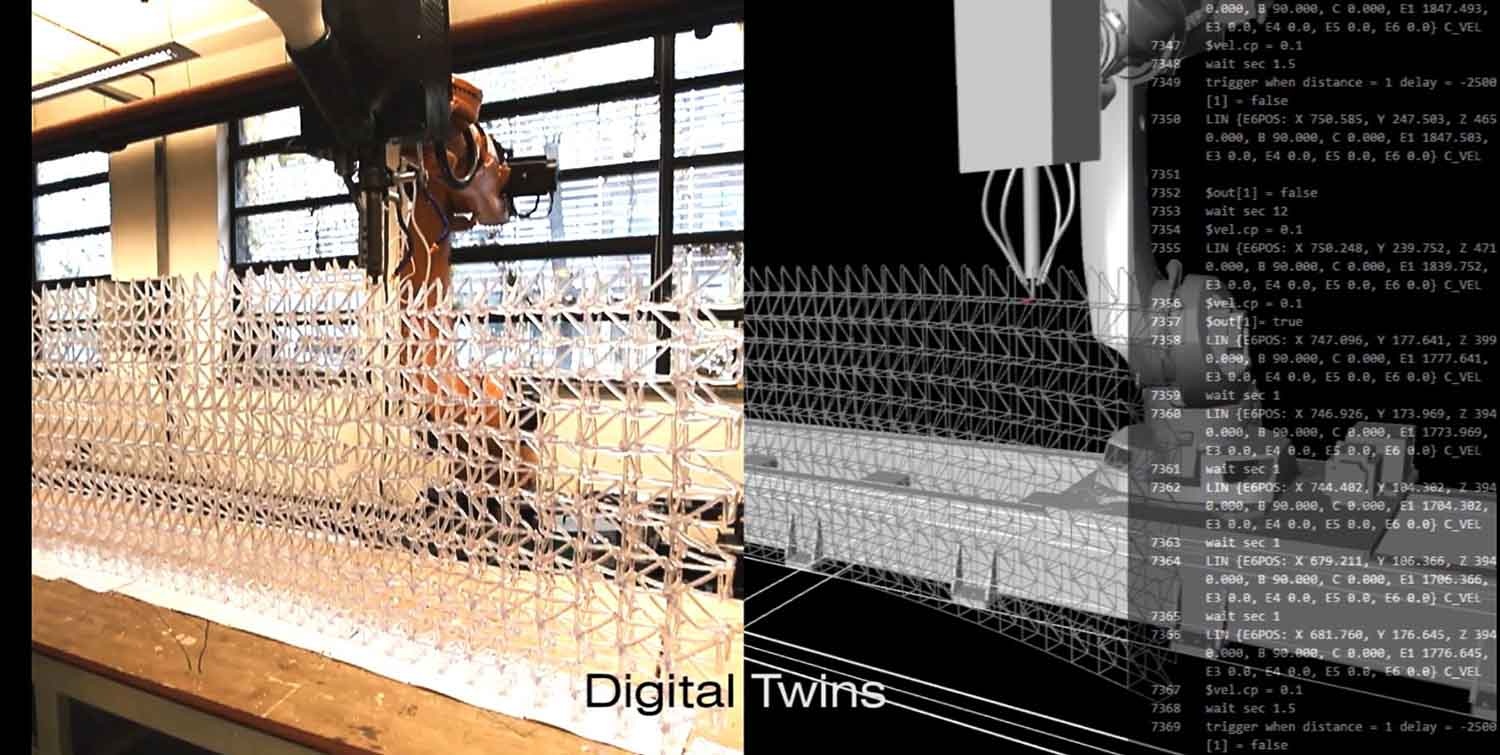

The robotic fabrication logic has been incorporated into the formation process. Then the continuous geometry of the pavilion is pixelated into a series of discrete components, each of which contains a unique crystalized printing tool-path. And as the stress on the overall form would be distributed into the pixels of the grid system, the entire network has to be modified into 5 types of different densities according to different structural performance along the surface.

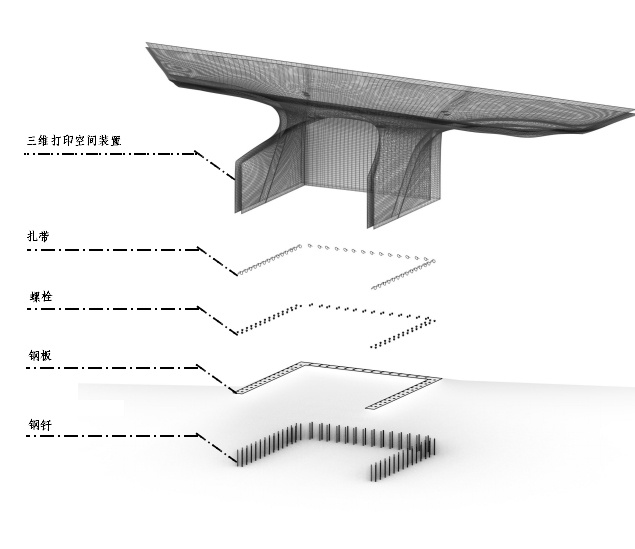

The pavilion is constructed by prefabricated production. The main part is divided into 50 different printing components at the early stage of the design according to the internal stress distribution in the structure. The prefabricated components, including the seat and base, are all packed and transported to the biennial Venice exhibition field after the completion of the prefabrication of the robot printing in Shanghai factory. The whole construction process integrates the process from off-site factory customization to on-site assembly.

Based on the support of digital design and robotic construction technology, the Cloud Village demonstrates the full integration of structural performance analysis technology with the designed form, and establishes a new model of production in building industry.

Project Name: Cloud Village

Principal Architect: Philip F. Yuan

Structural Engineer: Mike Xie

Design: Tongji University / Shanghai Digital Fabrication Engineering Technology Center

Digital Fabrication: Fab-Union

Projection Area: 110m2

Material: Modified Plastic, Steel Plate, High Strength Cable Ties

Design Stage: 2017.08 – 2018.01

Construction Stage: 2018.01 – 2018.05

Design Team:

Design: Chao Yan, Zheng Zhang, Xiang Wang

Structure: Jin Wang, Wei Shen, Qiang Zhou

Digital Fabrication: Wen Zhang, Lim Zhang, Zhewen Chen, Chenjun Liu, Sizhong He, Shilong Dai

Post-production: Zhe Guo

Image Source: Feng Yuan

1 / 31

show thumbnailsnext picture previous picture start slideshow close lightbox